|

|

|

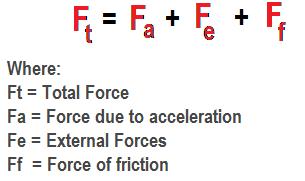

Lead screw forcesIt is important to understand the lead screw forces when selecting a screw assembly for a given application. Knowing the force on a lead screw is critical for calculating column or tensile loading and material selection. The following section will explain how to calculate theses forces. You may also find a Lead Screw Forces Calculator Here. Requirements before Proceeding (covered in proceeding sections)-Weight of assembly to be moved by the lead screw -Desired linear velocity of assembly (IPM) -Desired time to reach velocity (acceleration) -Linear Bearing type of assembly (ball bearing, sliding bearing) The formula for the total lead screw forces should be calculated as follows;

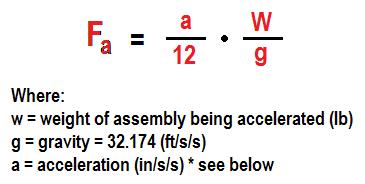

The most substantial of the lead screw forces is the acceleration force. So lets calculate that first. See the formula below.

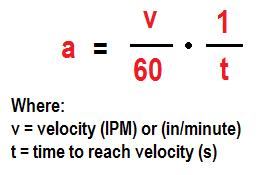

In the CNC industry, it is common to refer to the acceleration in terms of G or gravitational free fall. For example, some machines may run in 1 G operation. To convert G units into (in/s/s) simply multiply how many Gs by 386.08. So .5 Gs would = 193.04 in/s/s. If you do not know what acceleration you would like to achieve, it may help to think of a desired time to reach the acceleration profile. Then use the formula below to calculate acceleration.

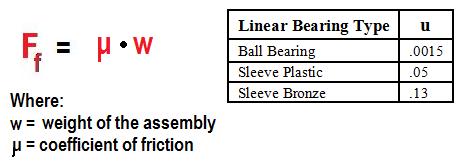

Next we need to find the Fe or external forces. The external forces for a CNC router are usually the weight for any assemblies being operated vertically and also the cutting forces. The cutting force is usually negligible for a CNC router in comparison to others. So if you do not know this then you shouldnt worry too much. For vertical operations, Fe = weight of the assembly being moved. Next: We find the forces due to friction. See the formula below.

If you are using linear ball bearings, the force due to friction should be negligible. However, if you are using a sleeve type bearing, the frictional forces may be substantial depending on the weight of your assembly. Next: We simply add all of these forces together to get a total of the lead screw forces. Example:Given that: Desired velocity = 400 IPM Desired time to reach velocity = 0.017 seconds Weight of the assembly = 50 lb Bearing type = Bronze sleeve on steel rod So A = 400 / 60 * (1 / .017) = 392 in/s/s Fa = (40 / 32.174) * (392 / 12) = 40.61 (lb-f) Fe = negligible since we arent in a vertical operation and maybe I plan on cutting foam so my cutting forces are very small. Ff = 50 * .13 = 6.5 (lb-f) Therefore Ft = 40.61 * 6.5 = 47.11 (lb) Go To: Steps for choosing a lead screw |

The Builder's Guide

Calculators

CNC Controllers

|

|

|

[?] Subscribe To This Site

Page Missing?Please bare with us as we upload pages. The website is still under contruction and new content is being added. To see the most recent pages, visit the website blog. Thank you! |

||

|

|

Homepage |

Buyer's Guide |

Builder's Guide |

Contact Us|

© Copyright 2007-2011. |

||

|

|

||